Unknown Facts About Aws Cwi

Table of ContentsFascination About Aws CwiAws Cwi Can Be Fun For AnyoneThe Aws Cwi IdeasExcitement About Aws CwiGet This Report about Aws Cwi

Have you ever before considered a job as a welding assessor? A welding inspection accreditation is not just a wonderful accomplishment, it validates your capacities in the welding market.

Ending Up Being a Licensed Welding Assessor shows your commitment to expanding within the welding market. This qualification is one that ought to not and will certainly not be ignored! As a CWI, you'll have the ability to make the most of a variety of different chances amongst industry experts.

As you might understand, welding is one of the most intricate solutions within the metal construction industry (https://www.figma.com/design/FRiLRXmmMFRuQGEzI6ECVz/Untitled?node-id=0-1&t=qzFSvhIwQu3JIjUn-1). The outcome of every welding job is extremely reliant upon specific welder ability.

Get This Report on Aws Cwi

There's no question that CWIs help to maintain greater degrees of consistency and high quality to the welding divisions they oversee. This post offers a brief summary of the primary benefits of functioning with a steel construction company that uses certified weld inspectors. It's not unusual that the majority of prominent sectors will certainly require you to hire certified welding assessors to supervise welding.

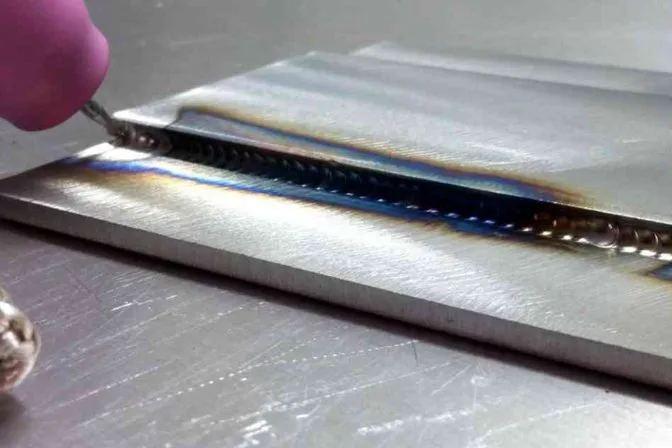

Certified welding assessors have years of experience and therefore, they recognize the nuances of compliance with welding codes. Adhering to the welding procedure, CWIs can perform a series of test to examine the quality of a weld, including visual assessment, warmth treatment and a hydrostatic test. Welding Inspection Service. They can likewise make the appropriate changes to the pre-weld preparation and the in-weld treatments as necessary

An in-house certified welding assessor will certainly be able to guarantee that your project is customized to all the demands of pertinent welding codes, guaranteeing its high quality. Welding inspectors can examine welding procedure requirements, structure and welding plans, devices calibration and welding materials. A welding assessors ability to offer welding procedure specs supplies the metal construction business a considerable side of the competition, permitting makers to develop welds that finest match private components, instead of using click for info reliable welds.

Aws Cwi Things To Know Before You Get This

As formerly mentioned, a CWI is not just responsible fore writing the treatments for the weld, yet likewise the quality-check screening treatments. https://businesslistingplus.com/profile/awscw1w3lding/. Past that, welding inspectors work to guarantee that tools is properly prepped for the work which welders have the ability to complete their welds with skills (Certified Welding Inspection). A qualified welding examiner will certainly have had years of experience, which a steel construction firm can take advantage of to make certain excellent end results for all manufacture jobs that entail welding

This is why it's vital to find a welding company with a seasoned and very educated in-house qualified welding inspector on personnel. CAMM steels is such a service, so call us today if you have an upcoming project that calls for high quality personalized welding! It's clear that a personalized steel construction supplier with internal CWIs has actually devoted to buying the quality of its welds.

In addition, some sectors need CWIs to be included in the production of components. Ultimately, CWIs presume a fair bit of duty, yet their experience reveals in the end product. Here at CAMM Metals, after the welding portion of the task is full, we use numerous in-house solutions. These services include weld evaluation with dye penetrant, acid cleansing and sprucing up of stainless steel welds.

For those customers that require qualified welds, we can accredit our welds to AWS D1.1 & AWS D1.6.

Excitement About Aws Cwi

It's crucial to keep in mind that lots of companies don't always need welders to be certified. The major difference is that certified welders have composed documents of their test outcomes and their performance is regularly monitored with periodic examination( s) being component of the efficiency document for each welder.

Before taking the examination all PFS welders are trained, if required, in the actual welding process that they will certainly be making use of and they will need to have a functioning knowledge of the welding equipment, welding palatable and the product to be welded. Successfully passing one examination will allow the welder to deal with many types of fabrications Will not permit him to work on all types of manufacture as there are credentials varies imposed for each test setup.

Essential variables include yet are not restricted to product kind, consumable kind, product density and welding position. and so on. After the welder has completed his examination plate or pipe the weld is inspected making use of the complying with NDE processes: Aesthetic Assessment X-Ray Liquid Penetrant Testing Sometimes, the weld is also destructively checked.

Aws Cwi Fundamentals Explained

PFS accomplishes this making use of a connection report that information all welds that a welder makes. If a welder does not use the welding process in a 6-month duration, then they will be requalified in that procedure. The advantages to using a qualification system are numerous yet the significant advantages are: It validates the skill of a private to perform according to a certified welding treatment specification (WPS) to generate a good weld.

Bug Hall Then & Now!

Bug Hall Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!